My Store

Custom High-Voltage Vacuum Feedthroughs for UHV

Custom High-Voltage Vacuum Feedthroughs for UHV

Couldn't load pickup availability

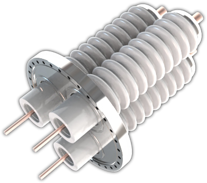

High-voltage vacuum feedthroughs provide hermetic electrical interfaces for transmitting kV-level DC or pulsed voltage across HV/UHV vacuum boundaries.

They are engineered for applications requiring high dielectric strength, stable insulation, and long-term reliability, including accelerators, vacuum instrumentation, and high-voltage research systems.

- Voltage range: kV-level (application dependent)

- Signal type: DC or pulsed high voltage

- Vacuum rating: HV / UHV compatible

- Insulation: ceramic-to-metal hermetic seal

- Polarity: positive or negative HV

- Operation: continuous or pulsed

What This Product Demonstrates

This page presents representative high-voltage vacuum feedthrough designs. Final assemblies are custom-engineered based on voltage level, insulation distance, flange standard, and vacuum environment.

Typical Applications

- Particle accelerators and beamline components

- Electrostatic lenses and deflectors

- High-voltage electrodes in vacuum

- Vacuum power supplies and test systems

- Scientific and industrial HV vacuum equipment

What Is a High-Voltage Vacuum Feedthrough?

A high-voltage vacuum feedthrough enables electrical power to pass from atmosphere into a vacuum chamber while maintaining electrical insulation and vacuum integrity.

The design relies on a ceramic-to-metal hermetic seal that provides both dielectric isolation and mechanical strength under high electric fields.

Key Design Considerations

- Electric field distribution and creepage distance

- Dielectric strength of ceramic insulator

- Surface flashover prevention

- Thermal and mechanical stress during bakeout

- Long-term stability under high voltage

Customization Options

- Maximum operating voltage (kV level)

- DC or pulsed voltage operation

- Single-pin or multi-electrode designs

- Flange type (CF / KF / custom)

- Ceramic length and diameter

- Grounding and shielding configuration

Engineering Specification Checklist

- Target voltage level (kV)

- DC or pulsed operation

- Vacuum level (HV / UHV)

- Bakeout temperature requirement

- Flange type and mechanical constraints

- Polarity and insulation clearance

- Environmental and safety requirements

Related Feedthrough Solutions

- Accelerator & BPM Feedthroughs

- RF & Microwave Vacuum Feedthroughs

- High-Current Vacuum Feedthroughs

- Custom & Hybrid Feedthroughs

FAQ

What voltage range can a high-voltage vacuum feedthrough support?

High-voltage vacuum feedthroughs can be designed for kV-level operation. The exact rating depends on ceramic geometry, insulation distance, and vacuum conditions.

Can high-voltage feedthroughs be used in UHV systems?

Yes. Properly designed ceramic-to-metal sealed feedthroughs are compatible with UHV environments and high-temperature bakeout.

Are these feedthroughs suitable for pulsed high voltage?

Yes. Designs can support both continuous DC and pulsed high-voltage operation, depending on application requirements.

Share