My Store

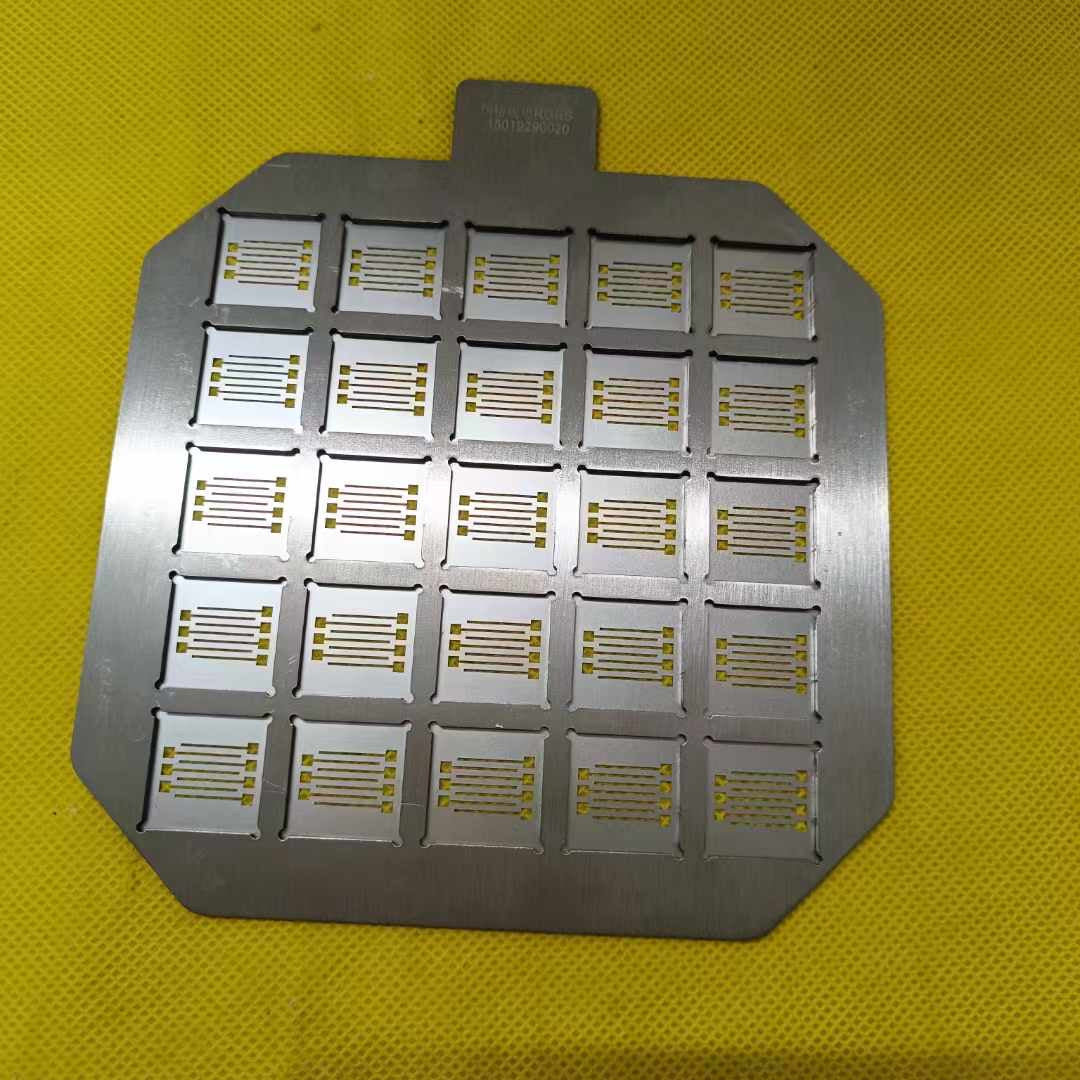

Custom Shadow Masks for Thin-Film Deposition

Custom Shadow Masks for Thin-Film Deposition

Couldn't load pickup availability

Shadow masks are precision-fabricated physical masks used for patterned thin-film deposition without photolithography. They are widely applied in thermal evaporation, e-beam evaporation, sputtering, and atomic layer deposition (ALD) processes, enabling direct material deposition through predefined openings onto substrates.

Unlike optical photomasks, shadow masks are placed in close proximity or direct contact with the substrate, allowing fast, resist-free pattern transfer. This makes them especially valuable for rapid prototyping, materials research, lift-off–free processing, and substrates incompatible with photoresists, such as flexible, temperature-sensitive, or chemically reactive materials.

We provide custom shadow masks manufactured from a variety of materials including stainless steel, nickel, molybdenum, tungsten, silicon, and quartz, selected based on deposition temperature, chemical compatibility, and feature size requirements. Advanced fabrication techniques such as laser cutting, chemical etching, and microfabrication are used to achieve precise apertures and tight tolerances.

Our shadow masks support custom geometries, fine feature sizes, and high positional accuracy, suitable for applications ranging from electrode patterning and device fabrication to research-scale thin-film experiments. Single-use and reusable designs are available to meet different throughput and contamination-control needs.

Feel free to send your design (even a hand-drawn sketch) to us (support@design-realized.com). Our engineers will help you realize your custom shadow mask.

Key Features & Capabilities

- Resist-free patterning for thin-film deposition

- Compatible with evaporation, sputtering, and ALD

- Custom materials and thickness options

- Fine feature sizes and tight tolerances

- Rapid turnaround for prototyping and R&D

- Reusable or single-use designs available

Typical Applications

- Thin-film electrode patterning

- Semiconductor and MEMS device fabrication

- Organic electronics (OLED, OPV)

- Sensors and microelectronic devices

- Research and rapid prototyping

- Lift-off–free deposition processes

Key Specifications:

- Thickness Range: 0.01mm to 5mm

- Tolerance: ±0.002mm for exceptional accuracy

- Feature Resolution: Minimum width of features as small as 0.02mm

Frequently Asked Questions — Shadow Masks

What is a shadow mask?

How is a shadow mask different from a photomask?

What deposition methods are compatible with shadow masks?

What materials are available for shadow masks?

What is the minimum feature size you can achieve?

Are shadow masks reusable?

Can shadow masks be customized?

Are shadow masks suitable for research and production?

📘 Related Knowledge

Share