My Store

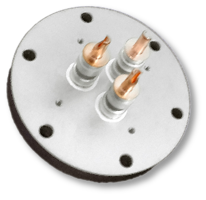

Custom High-Current Vacuum Feedthroughs for UHV Power

Custom High-Current Vacuum Feedthroughs for UHV Power

Couldn't load pickup availability

High-current vacuum feedthroughs provide hermetic electrical interfaces for transmitting high-amperage power across HV/UHV vacuum boundaries.

They are engineered for applications requiring stable current delivery, low contact resistance, and thermal reliability, such as heaters, filaments, magnets, and high-power experimental systems.

- Current range: tens to hundreds of amperes (application dependent)

- Signal type: DC or low-frequency power

- Vacuum rating: HV / UHV compatible

- Conductor: solid metal pin or high-current rod

- Thermal design: optimized for continuous operation

- Mounting: CF / KF / custom flange

What This Product Demonstrates

This page shows representative high-current vacuum feedthrough designs. Final products are custom-engineered based on current level, duty cycle, thermal constraints, and mechanical integration.

Typical Applications

- Vacuum heaters and heating stages

- Filament and cathode power feeds

- Electromagnets and solenoids

- Vacuum furnaces and thermal processing systems

- High-current laboratory test chambers

What Is a High-Current Vacuum Feedthrough?

A high-current vacuum feedthrough allows electrical power to pass from atmosphere into a vacuum chamber while maintaining vacuum integrity and electrical isolation.

Unlike signal feedthroughs, high-current designs focus on conductor cross-section, contact resistance, and heat dissipation to ensure stable operation under continuous load.

Key Design Considerations

- Maximum continuous and peak current

- Conductor material and cross-sectional area

- Thermal rise and heat dissipation

- Contact resistance and mechanical stability

- Compatibility with vacuum bakeout

Customization Options

- Maximum current rating (A)

- Continuous vs pulsed operation

- Single-pin or multi-conductor layouts

- Flange type and size

- Conductor length and termination style

- Thermal management considerations

Engineering Specification Checklist

- Target current (A) and duty cycle

- Operating voltage (if applicable)

- Vacuum level (HV / UHV)

- Bakeout temperature requirement

- Flange standard and mechanical constraints

- Termination type (stud, lug, cable, custom)

Related Feedthrough Solutions

- Accelerator & BPM Feedthroughs

- RF & Microwave Vacuum Feedthroughs

- High-Voltage Vacuum Feedthroughs

- Custom & Hybrid Feedthroughs

FAQ

What current levels can high-current vacuum feedthroughs support?

High-current vacuum feedthroughs can be designed for tens to hundreds of amperes, depending on conductor size, thermal design, and duty cycle.

Can high-current feedthroughs operate continuously?

Yes. Designs can support continuous current operation when thermal rise, contact resistance, and cooling constraints are properly addressed.

Are high-current feedthroughs compatible with UHV and bakeout?

Yes. With suitable materials and sealing methods, high-current feedthroughs can be designed for UHV environments and high-temperature bakeout.

Share