My Store

Custom 4H-SiC Substrates & Wafers for Power & RF Devices

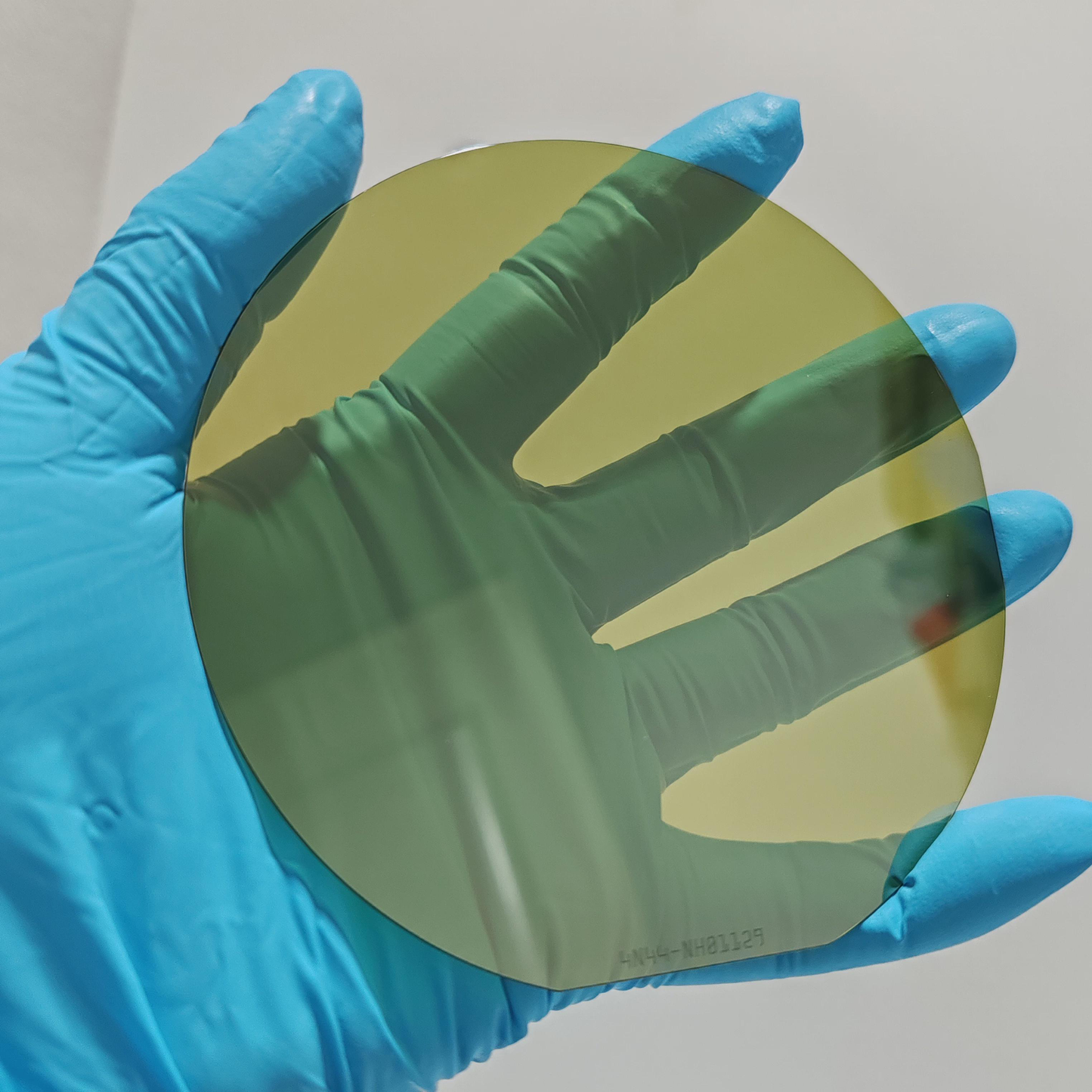

Custom 4H-SiC Substrates & Wafers for Power & RF Devices

Couldn't load pickup availability

4H-SiC (Silicon Carbide) single crystal substrates and wafers are industry-standard materials for next-generation wide-bandgap power electronics. With a bandgap of approximately 3.26 eV, high thermal conductivity, and an exceptionally high critical electric field, 4H-SiC enables high-voltage, high-power, and high-frequency devices that outperform conventional silicon technologies.

Compared with silicon, 4H-SiC offers significantly higher breakdown voltage, lower on-state losses, and superior thermal stability, making it ideal for power devices operating in harsh environments and at elevated temperatures. Its hexagonal polytype structure provides excellent electron mobility along the c-axis, which is why 4H-SiC is the preferred polytype for MOSFETs, Schottky diodes, JFETs, and RF power devices.

Our 4H-SiC substrates are produced with strict control of crystal quality, micropipe density, and surface morphology, ensuring reliable epitaxial growth and device fabrication. Precision polishing delivers low surface roughness and high flatness, compatible with advanced epitaxy techniques such as CVD and MBE.

Multiple wafer diameters, doping types, and orientations are available to support both academic research and commercial semiconductor manufacturing. Custom specifications, including thickness, resistivity, and surface finish, can be provided upon request.

Key Features & Properties

- Polytype: 4H-SiC

- Wide bandgap: ~3.26 eV

- High breakdown electric field

- Excellent thermal conductivity

- High electron mobility along c-axis

- Low defect density and smooth surface finish

- Suitable for high-temperature and high-power operation

Typical Applications

- Power MOSFETs and Schottky barrier diodes

- High-voltage and high-efficiency power modules

- Electric vehicles (EV) and fast-charging systems

- Renewable energy and smart grid inverters

- RF and microwave power devices

- Aerospace and harsh-environment electronics

Properties:

| Conduction Type | N-type |

| Poly Type | 4H |

| Class | P-MOS |

| Diameter(mm) | 150±0.25mm |

| Thickness(um) | 350um±25um |

| Orientation<11-20> | 4±0.5°off toward <11-20> |

| Primary Flat Position (degree) | <1120>±3° |

| Primary Flat Length(mm) | 47.5mm±2.5mm |

| Dopant | N-type Nitrogen |

| Resistivity(Ω•cm) | 0.015-0.025 |

| MPD(per cm²) | ≤0.1/cm2 |

| Surface Process(Si face) | CMP, <0.2 nm |

| Surface scratch | Total Length≤7.5cm |

| LTV(um) | ≤ 2um(10*10mm) |

| TTV(um) | ≤5um |

| Warp(3P)(um) | ≤20um |

| Bow(3P)(um) | ≤15um |

| TSD Defect | ≤200ea/cm2 |

| BPD Defect | ≤500ea/cm2 |

| EPD Defect | ≤2700ea/cm2 |

Frequently Asked Questions — 4H-SiC Substrates & Wafers

What is 4H-SiC and why is it widely used?

How does 4H-SiC compare with silicon?

Why is 4H-SiC preferred over other SiC polytypes?

What wafer sizes, doping, and orientations are available?

What surface quality can be achieved?

Are these wafers suitable for epitaxial growth?

What applications commonly use 4H-SiC wafers?

Do you provide epitaxial layer growth services?

Are these wafers suitable for both research and mass production?

📘 Related Knowledge

- Diamond-on-SiC Services for Ultra-High-Power & Thermal Management

- AlN-on-SiC Services for RF

- GaN-on-SiC Services for RF

- 4H-SiC for RF

- Epitaxial Wafer Growth on 4H-SiC Substrates

- 4H-SiC Substrate & Wafer — Wide Bandgap Power Semiconductor Guide

- 4H-SiC Single Crystal and Wafer Guide for Power Semiconductor Devices

- What Scientists Must Prepare Before Ordering Custom Crystals

Share